MenuProductsPRODUCT DISPLAY

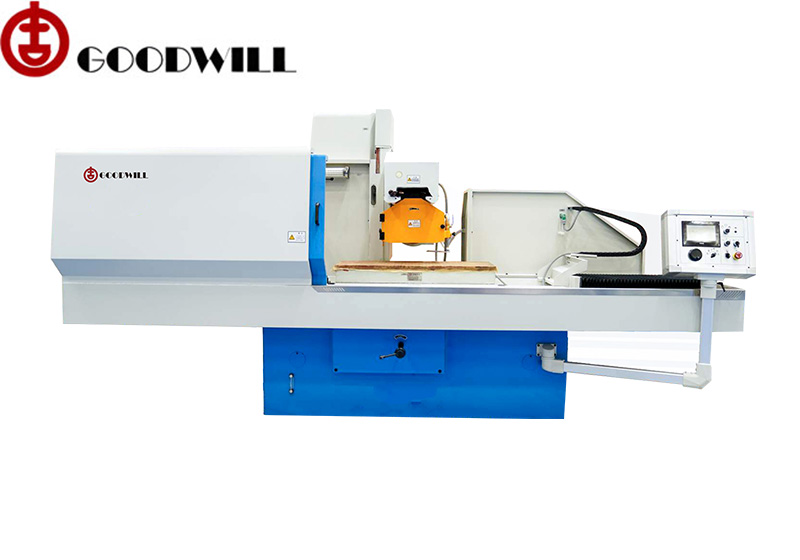

- V type duplex grinder

- Rotary table grinder

- T type centerless grinder

- T type surface grinder

- Double column grinder

- Cylinder grinder

- Honing machine

- Gear grinder

- Roll grinder

- Valve ball grinder

- Vertical double disc

- Bearing grinder

- Screw thread Grinder

- Vertical complex grinder

- Casting grinder

- C type centerless grinder

- CNC forming grinder

- Deburring machine

- Crankshaft grinder

- H type double surface

- Internal grinder

- Optical curve grinder

- C type surface grinder

- Tool grinder

Introduction

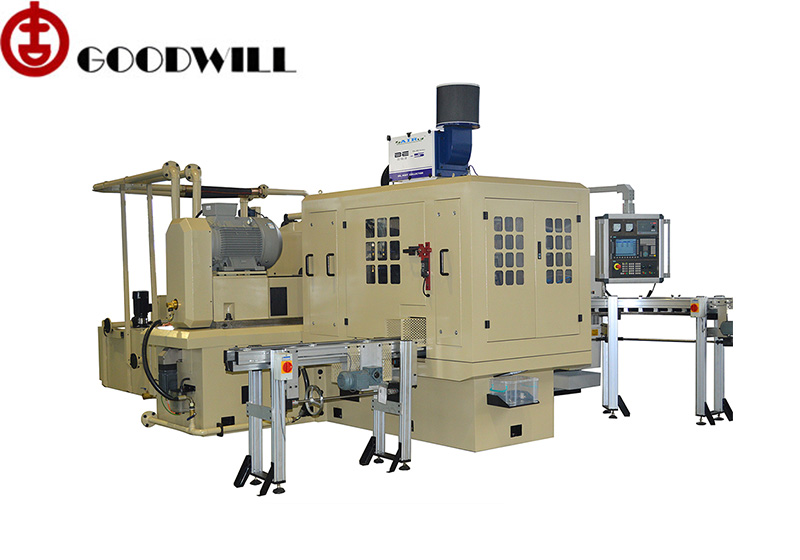

Vertical type Duplex grinding machines, use fixed abrasive in lieu of loose abrasive for precision finishing.

Depending upon the application, fine grinding technology utilizes fixed abrasive diamond or CBN suspended in resin,

metal, and vitrified bonds to grind a wide range of materials to very tight specifications. Fine grinding technology uses

similar planetary machine designs and kinematics to traditional lapping technology, with several significant advantages.

Fine grinding offers several advantages over the traditional lapping process yet still yielding similar flatness, parallelism,

surface finish, and size tolerances. The fine grinding process is much cleaner than lapping, virtually eliminating swarf disposal and work piece cleaning issues.

This process is also typically 3-20 times faster than lapping, blurring the lines between traditional lapping and grinding technologies.

中文

中文  English

English

+86-189-12765130

+86-189-12765130