MenuProductsPRODUCT DISPLAY

- V type duplex grinder

- Rotary table grinder

- T type centerless grinder

- T type surface grinder

- Double column grinder

- Cylinder grinder

- Honing machine

- Gear grinder

- Roll grinder

- Valve ball grinder

- Vertical double disc

- Bearing grinder

- Screw thread Grinder

- Vertical complex grinder

- Casting grinder

- C type centerless grinder

- CNC forming grinder

- Deburring machine

- Crankshaft grinder

- H type double surface

- Internal grinder

- Optical curve grinder

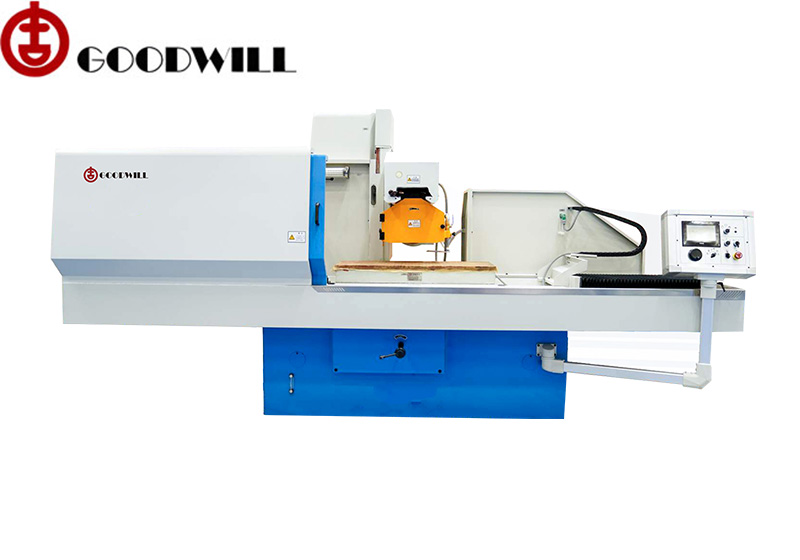

- C type surface grinder

- Tool grinder

Introduction

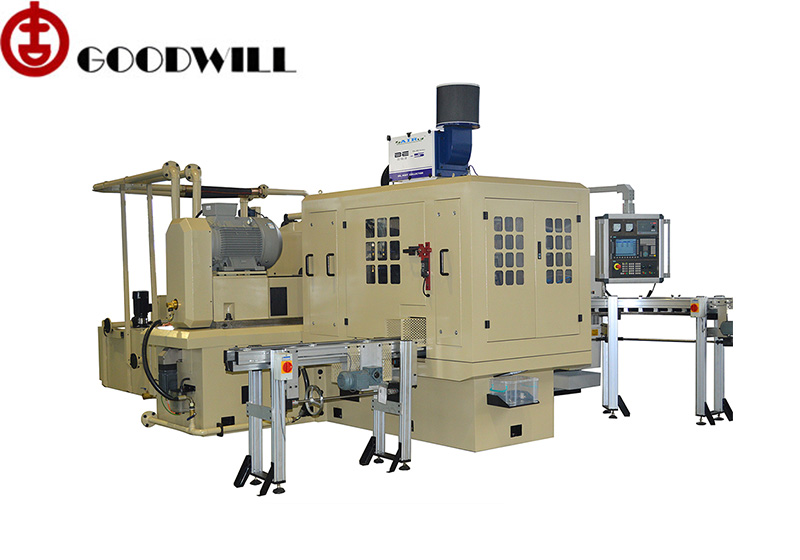

The machine’s parts such as body, connectors and lifting platform are all high-quality HT350 castings after stress relieving by means of annealing treatment and aging treatment.

Because of optimized design after computing based on the finite element analysis method, these castings are rigid because of their proper structural strengths and reinforcing ribs.

*High accuracy in axial movements is guaranteed by THK C3 ball screws and preloaders, THK UP guide rails and full-closed 0.0001mm grating scales.

*The high-precision motorized spindle has a speed of 24,000Rrpm.

*The high-precision projection system (20X, 50X) has an ultra-long life because of energy-saving LED light sources for both transmitted light and vertical light.

*The control system can improve the machining efficiency by means of 4-axis linkage (2-axis interpolation).

中文

中文  English

English

+86-137-7171-3641

+86-137-7171-3641